Most current electric vehicles, including all Tesla vehicles, use a 400-volt architecture, but the Porsche Taycan surprised everyone when it was launched with an 800-volt architecture. The Taycan did not impress with its range when it was launched, but the 800-volt system was optimized for fast charging and efficiency. It’s not by chance that the 800-volt system was adopted by a sports car manufacturer. Porsche took inspiration from its LMP-1 race car, which used the higher voltage architecture.

The 800-volt architecture: what are the advantages?

Before we discuss the major benefits of using a higher voltage architecture, let’s talk about the 400-volt system that most EV makers still use today. This can be traced back to the time when hybrid vehicles like the Toyota Prius were the first mass-produced electrified vehicles. Their electric motors and batteries used the 400-volt system, so, naturally, the first electric vehicles adopted this system as well. The 400-volt system was also compatible with the existing electrical infrastructure.

The switch to an 800-volt system allows for a big efficiency jump

Lucid already demonstrated that with the Air, which is currently the most efficient electric car ever made. Lucid uses a 924-volt system actually, and it’s one of the reasons the Lucid Air was able to achieve its 520-mile range. Having such a high voltage allows for supplying the same amount of power with a lower current, which means fewer losses to heat in the power system.

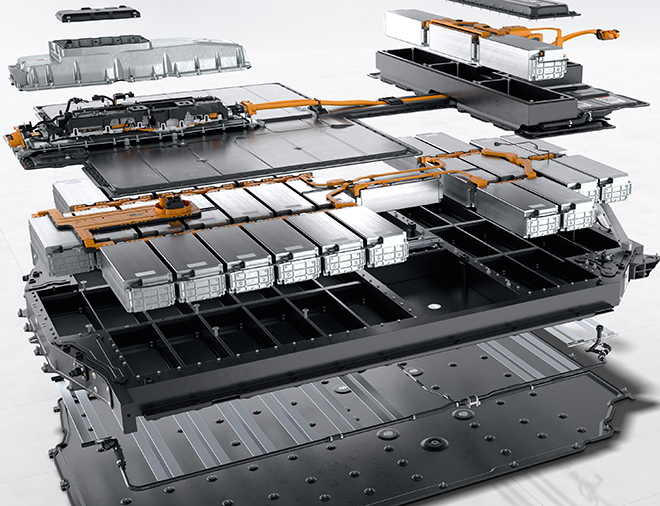

800-volt systems bring with them a wide variety of benefits, including lower weight, higher thermal efficiency, and potentially greater range. At the same time, lower current means that thinner wires can be used in the electric system and less copper in the electric motors, reducing weight even further. But their biggest benefit is arguably significantly faster public charging.

The higher voltage allows for a higher charging speed because the lower current reduces the overheating in the charging cables and associated hardware. The power loss increases exponentially with heat, so you see why this is a big deal. Lastly, faster-charging speeds allow

for more efficient energy recovery during braking, so more of the lost energy goes back into the battery and less into the air as heat.

Why is an 800-volt system better?

In short, the higher the voltage, the greater the efficiency. First introduced in racing series such as the Formula E global electric championship, 800-volt systems allow electricity to move from the battery to the wheels with lower current, which reduces the power lost to heat. The higher voltage and lower current means that the same amount of power can be moved using thinner wires, and it also means that less copper needs to be used in the motors themselves – this reduces their weight and also allows them to spin even faster, allowing higher performance. A simplified analogy is a power drill: the higher the voltage, the more powerful it is – and the faster it charges.

Faster charging is enabled with an 800-volt system because lower current reduces overheating in the charging cables and associated hardware – less power is lost to heat, and more is delivered to your car’s battery (power loss increases quadratically, i.e., to the fourth power, with current, so reducing the current has a huge effect on efficiency). Using similar cables and plugs, charging time can be dramatically improved. For instance, the Porsche Taycan, one of the few vehicles currently available with 800-volt systems, can charge its battery from 5 to 80 percent in 22.5 minutes on a 270-kW 800-volt level 3 charger, while the same amount of charge on a 50-kW, 400-volt level 3 charger takes up to 90 minutes.

Why do so few EV makers use an 800-volt architecture today?

Currently, besides the Porsche Taycan and the other models built on the same platform, like the Audi e-Tron GT, only the Lucid Air, Hyundai Ioniq 5, and the Kia EV6 use the 800-volt architecture. The Hyundai Group’s vehicles demonstrated how the higher voltage approach can be scaled down to more affordable models, without affecting the price. The Hyundai Ioniq 5 and Kia EV6 have great charging speeds and can add 68 miles of charge (108 km) in five minutes when connected to a fast 350-kW DC charger.

At the moment, 800-volt electrical systems are not commonplace in electric vehicles. The Porsche Taycan was the first EV available with an 800-volt architecture; its relative, the Audi e-Tron GT, also has an 800-volt system, as do the Hyundai Ioniq 5 and Kia EV6. Rivian and General Motors have both announced that their upcoming products are 800-volt ready, and both plan to introduce 800-volt systems along the way, with GM committing to an 800-volt option for its new Ultium battery architecture. Startup brand Lucid actually has a 920 (!)-volt system for its new Lucid Air sedan, which has just hit the market. Global supplier Delphi sees a broad shift towards 800-volt architectures for premium EVs, followed by rapid adoption by mainstream brands.

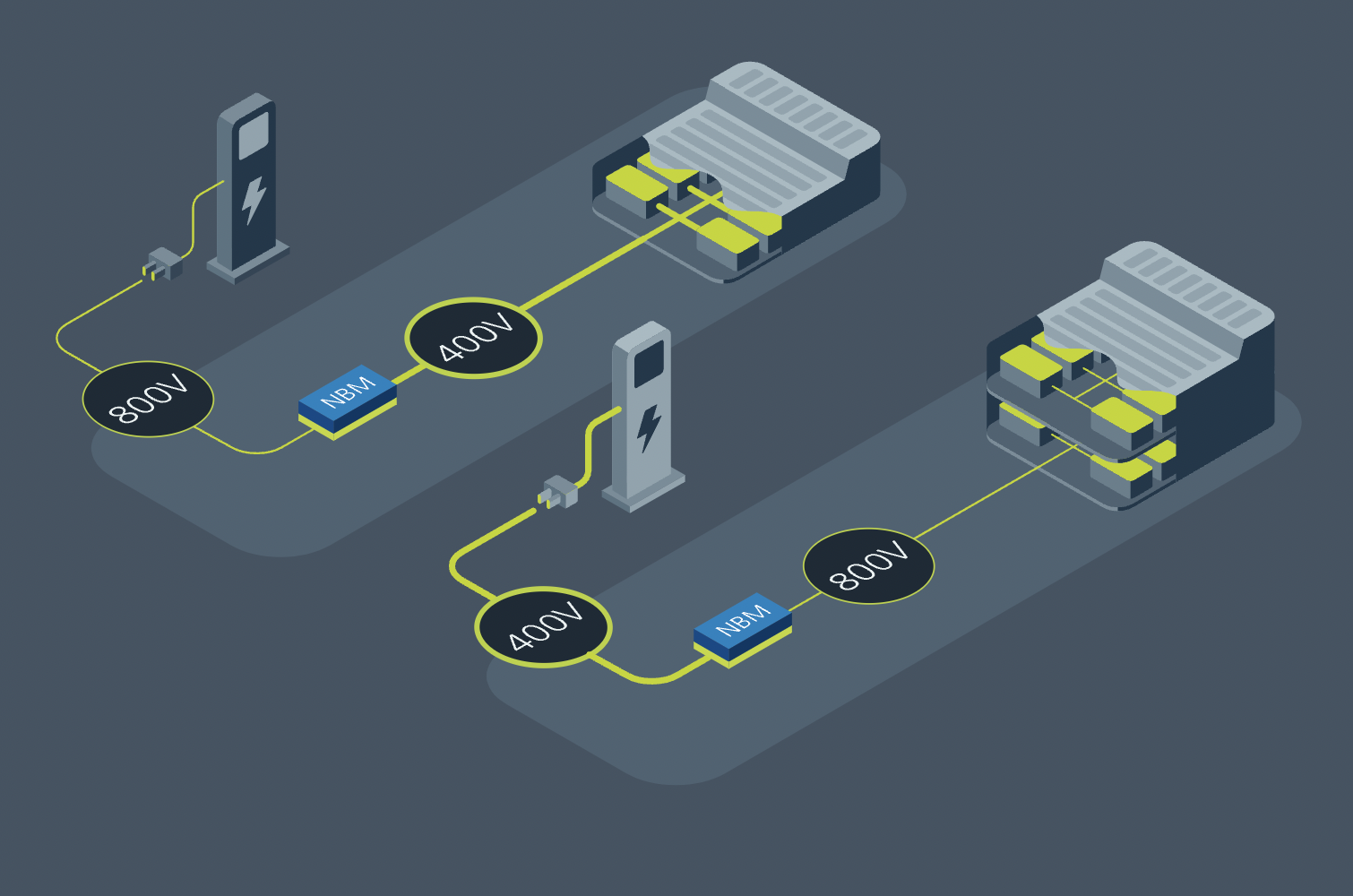

The move to 800 volts requires not just the cars to be enabled

It needs charging equipment that can take advantage of that architecture. Most level 3 chargers run on 400-volt systems and can deliver from 50 to 150 kW; 800-volt chargers can deliver up to 350 kW but are still not very common. Ionity, Tritium, and Electrify America are the biggest players, with most offering at least one 350-kW charger alongside multiple 150-kW chargers in convenient locations.

As with any other technology, the roll-out of 800-volt systems and the charging infrastructure to support them will happen rapidly. While currently a “premium” technology, it’s already spreading to more mainstream car brands, and the increased convenience that super-fast charging offers will be irresistible to the EV owners of the future.