Triple Hyper9 Powered EV Cadillac Coupe Deville

Restoring Elegance: The Transformation of a 1966 Cadillac DeVille

Year, Make, Model: 1966 Cadillac DeVille

The resurrection of a classic begins with the 1966 Cadillac DeVille—a symbol of automotive elegance and innovation. From its overall weight to the meticulous restoration time, each aspect of this vintage gem contributes to its revival.

Vehicle Name: DeVille

The name DeVille resonates through automotive history, and this restoration project breathes new life into the iconic vehicle, preserving its legacy for generations to come.

Overall Vehicle Weight: 5,800 pounds

At 5,800 pounds, the DeVille stands as a heavyweight in the realm of classic cars. This substantial weight is a testament to its robust build, harking back to an era where size and luxury went hand in hand.

Amount of Time to Build: Full restoration in eight months

In a remarkable feat of craftsmanship, the restoration team dedicated eight months to the meticulous revival of the DeVille. Every detail, from the motor to the interior, underwent a careful and deliberate reconstruction.

Cost to Build: $220,000

Quality comes at a price, and the restoration journey of the DeVille was no exception. With a total cost of $220,000, this project stands as a testament to the commitment to excellence and the preservation of automotive heritage.

Motor / Drivetrain: Powering the Legacy

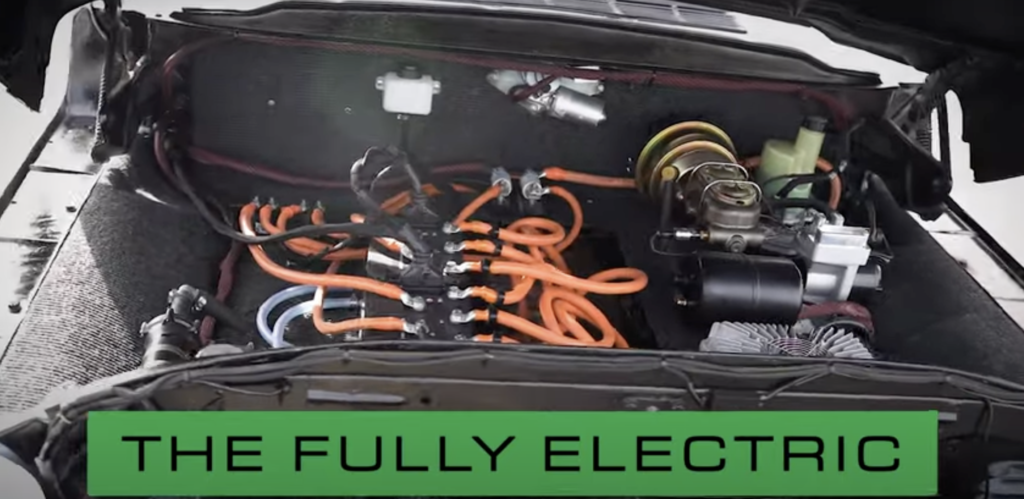

Motor Swap Performed By: Legacy EV

Legacy EV takes the helm in the motor swap, breathing new life into the DeVille’s drivetrain. The result is a seamless integration of modern power into a classic masterpiece.

Motor Drive Unit: 3 inline Hyper9 Motors

With three inline Hyper9 Motors, the DeVille roars back to life with 394 horsepower and an impressive 1000 lb-ft of torque. The marriage of Legacy EV’s expertise and cutting-edge technology propels this classic into the future.

Motor Control Software: Netgain SmartView Motor Software

SmartView Motor Software becomes the brain of the operation, ensuring optimal performance and efficiency. The integration of advanced control software enhances the driving experience while maintaining the classic charm.

Batteries: NMC Lithium Ion

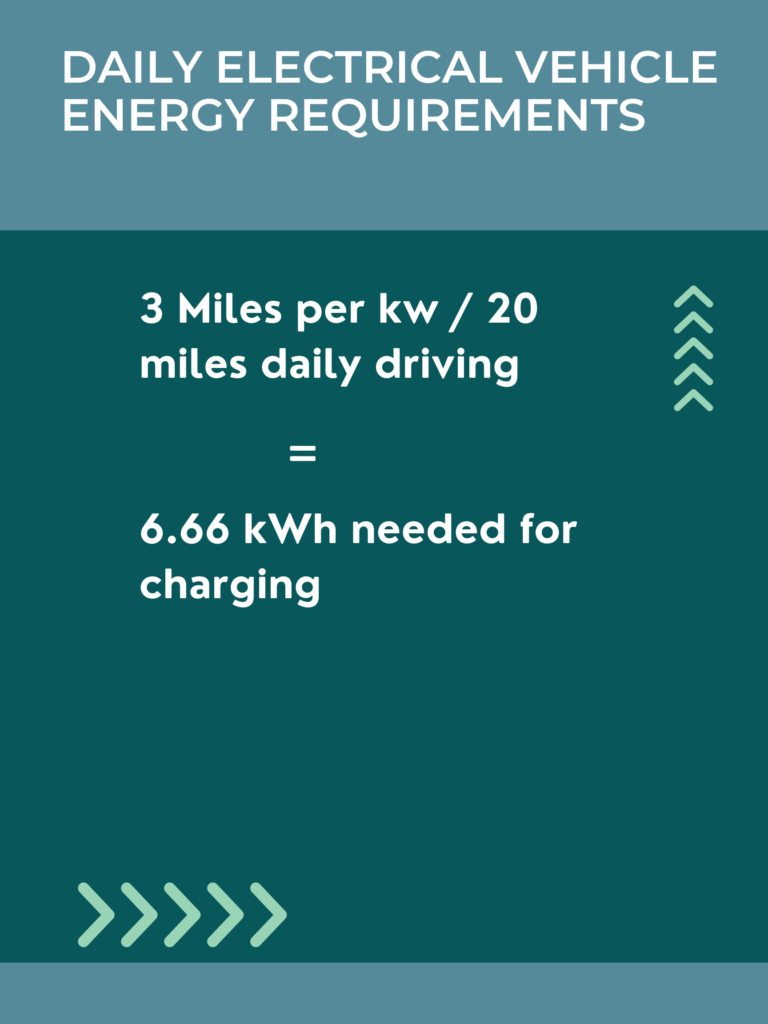

The DeVille’s electric transformation is powered by NMC Lithium Ion batteries, boasting 500 amp-hours (55.5 kWh) of energy. This modern upgrade ensures longevity and sustainability on the open road.

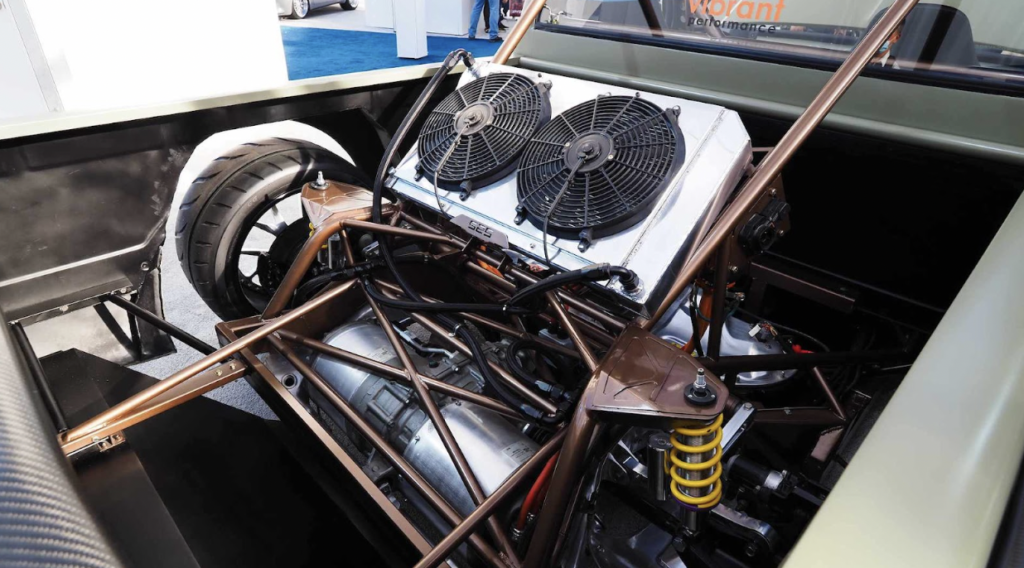

Chassis/Suspension: Navigating Comfortably

Installation Shop: Legacy EV

Legacy EV’s expertise extends to the chassis and suspension, where stock components receive an expert touch. The result is a DeVille aligned with contemporary standards of comfort and handling.

Air Suspension Management System: Airlift

Airlift’s air management system introduces a dynamic element to the suspension, allowing for personalized adjustments. The DeVille glides over roads with newfound agility, courtesy of Legacy EV and Airlift.

Body/Paint: A Visual Symphony

Paint Shop: Burges Customs

Burges Customs takes the brush to the DeVille, bringing it back to life with a coat of Bright White paint. The result is a visual symphony that pays homage to the original color while radiating a timeless appeal.

Headlights and Taillights: LED Illumination

The restoration extends beyond mechanics, with LED headlights and taillights illuminating the road ahead. This modern touch ensures visibility and safety without compromising the classic aesthetic.

Interior: Blending Heritage with Modern Comfort

Gauges: Dakota Digital

Dakota Digital gauges adorn the interior, seamlessly merging classic design with contemporary functionality. The DeVille’s dashboard becomes a captivating display of information and nostalgia.

Steering Wheel: PearlCraft

PearlCraft’s steering wheel adds a touch of sophistication to the interior, inviting drivers to experience the road with both style and comfort.

A/C System: Legacy EV A/C System

Even the air inside the DeVille carries a touch of legacy, thanks to Legacy EV’s air conditioning system. Comfort meets tradition as the interior remains cool and inviting.

In the meticulous restoration of the 1966 Cadillac DeVille, each specification contributes to a symphony of craftsmanship, blending the timeless allure of classic automobiles with the innovations of the present. The DeVille stands not just as a car but as a revived icon, ready to grace the roads with elegance and power.

SPECS

- Year, Make, Model: 1966 Cadillac De Ville

- Vehicle Name: DeVille

- Overall Vehicle Weight: 5,800 pounds

- Amount of Time to Build: Full restoration in eight months

- Cost to Build: $220,000

Motor / Drivetrain

- Motor Swap Performed By: Legacy EV

- Motor Drive Unit Year, Make, Model: 3 inline Hyper9 Motors

- Horsepower/Kilowatt: 394 hp (292.5 kW)

- Torque/Newton Meters: 1000 lb-ft

- Motor/Transmission mounts: Legacy EV

- Control Software: SmartView Motor Software

- Batteries: NMC Lithium Ion

- Number of amp-hours: 500 (55.5 kWh)

Chassis/Suspension

- Installation Shop: Legacy EV

- Chassis: Stock

- Lift/Lowering Kit: Legacy EV

- Control Arms: Stock

- Spindles: Stock

- Springs: Stock

- Air Management System: Airlift

- Shocks: Gas

- Fuel tank: Battery Boxes!

Wheels, Tires & Brakes

- Front Wheel Brand, Size, Width, Backspacing: 22in EVOD Wheels

- Front Brakes: Stock

- Rear Brakes: Stock

- Gears/Ratio: Stock

- Axles: Stock

- Driveshaft: Shortened Two piece

Body/Paint

- Paint Shop: Burges Customs

- Color: Bright White

- Headlights: LED

- Taillights: LED

- Rubber Moldings: Caddy Daddy

Interior

- Gauges: Dakota Digital

- Steering Wheel: PearlCraft

- A/C System: Legacy EV A/C System